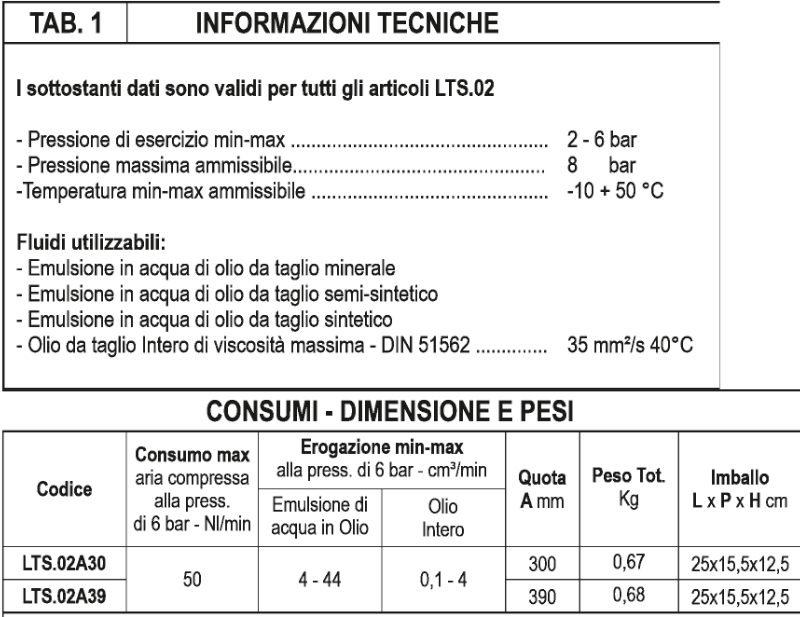

Code LTS.02

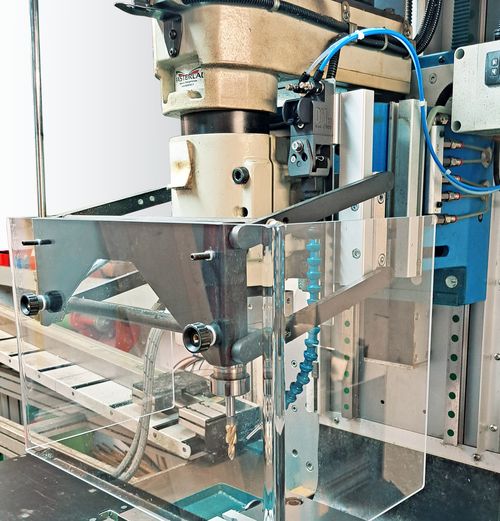

The Lubrorefrigerator model LTS.02 is a pneumatic device designed to lubricate and cool the tool and workpiece on vertical spindle machine tools, such as bench drills, column drills, radial drills, drill-mills, toolmaker milling machines, universal milling machines, CNC milling machines, and general machine tools. These machines require frequent work changes and consequent repositioning and tool changes.

The device uses the principle of Minimal Lubrication, also known as MQL: Minimum Quantity Lubrication. It performs its function by supplying compressed air and minimal amounts of lubricating fluid.

All OilJet products are optimized for the use of neat lubricating oils, typically based on synthetic vegetable esters, as well as the more well-known water-miscible cooling lubricants. The LTS.02 is a professional product, offered in a single “full optional” version with Tubo-flex in two different lengths.

The device is specifically designed for frequent and “close” use by the operator. This is made possible by the particular design of the Venturi system, placed inside the mixing unit (hereafter referred to as the “Console”), and the internal delivery nozzle, which allows fluid delivery with limited atomization, particularly when using water-miscible cooling lubricants.

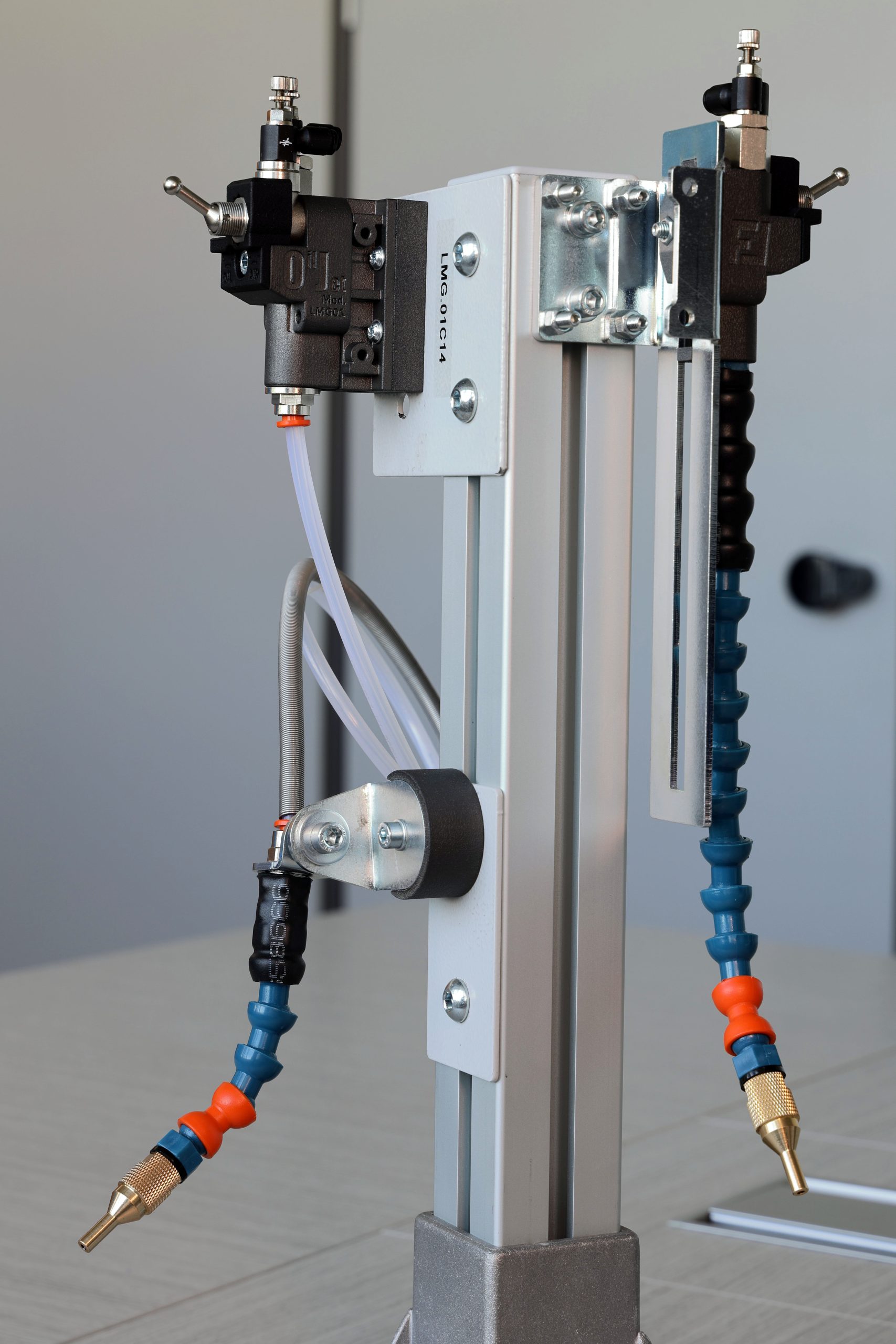

The wide versatility of the LTS.02 family is enhanced by a series of optional accessories that further extend its range of applications.

All models utilize the Venturi principle, whereby the fluid is drawn from the reservoir and subsequently mixed with compressed air. This occurs differently between the two macro-families: LMG01 +01, compared to LTS.02. The final result is very similar, with more or less pronounced predispositions towards certain uses, as described below.

They are designed to use all commonly known cooling lubricants indiscriminately, as described below. They do not provide for the collection and reuse of the used fluid, as the modest quantities dispensed partially deposit on the workpieces, helping to protect them from oxidation, evaporate spontaneously, and partially disperse among processing waste. The target machines are those described in the various technical sheets of each model, extending to special machines and various equipment for mechanical processing. In fact, based on the characteristics of a specific “special machine,” it is possible to opt for one or another model.

As clearly defined in their respective user and maintenance manuals, for safety and overall consistency, OilJet products are not intended to replace the original continuous fluid cooling system. Beyond certain limits of capacity and severity of certain machines, the performance guaranteed by minimal systems (MQL) would not be sufficient to dissipate the heat generated between the tool and the workpiece.

In conclusion, the ideal recipient machines for installing these products can be defined as belonging to the categories: “chip-removing machine tools and small to medium-sized deformation machines.” For clarity, deformation machines (which are certainly less known) are those that perform their work by “deforming” the metal, such as presses in general and profiling plants.

Where the type and size of the hosting machine allow, OilJet products enable the removal of the old continuous fluid cooling system, with evident advantages in terms of bulk, stagnation of degraded fluids (especially in cases of sporadic use) and consequent disposal, general cleanliness of the surrounding environment, and greater protection of the plastic shields of safety guards.

Each model is developed with a concept of maximum modularity (most additional kits and spare parts are common to all OilJet models). This general flexibility also allows for the development of custom-made products, especially for installations on series machines.

SOME EXAMPLES OF USE:

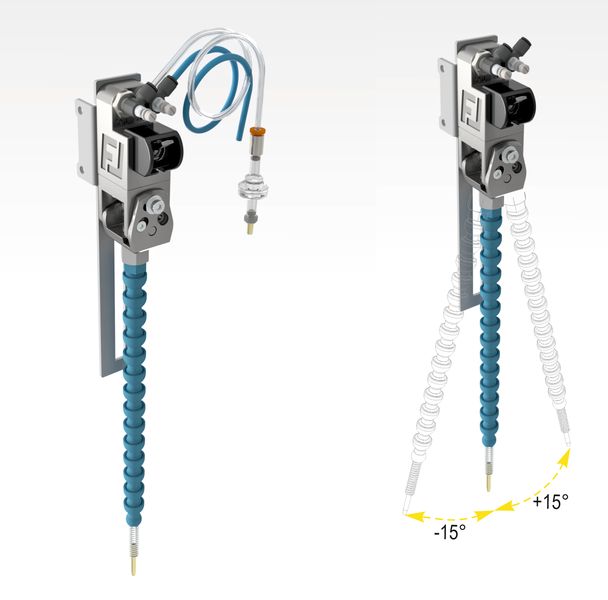

Example 1: For a vertical spindle machine (e.g., Drill-Milling Machine) that requires frequent tool changes, with probable variation in its own length, the LTS.02 model is preferred, as it is equipped with a “joint” at the base of the flex tube for quick disengagement of the work area, as well as having a friction-type axial adjustment (common to other models). All this results in maximum versatility and speed of use.

Example 2: For a machine with a delivery point distant from the optimal operating point, or to be placed at a distance for safety reasons, the LMG.01.C model is recommended, as it has a satellite nozzle version, that is, detached from the console and supported by its own magnetic base. With the addition of the magnetic base kit for the console support, maximum versatility is achieved.

The classic recipient machine for the LMG.01.C model is the classic Parallel Lathe, as demonstrated in the general presentation video of the OilJet range.

Example 3: For an occasional use machine, on which it might be inconvenient to permanently fix a unit, the most suitable model for the specific case could be used, combined with the optional magnetic base kit, applicable to all OilJet models.

This is a pneumatic device designed to lubricate and cool the tool and workpiece on vertical spindle machine tools, such as bench drills, column drills, radial drills, drill-mills, toolmaker milling machines, universal milling machines, CNC milling machines, and general machine tools. Therefore, machines that require frequent work changes and consequent repositioning and tool changes.

The device uses the principle of Minimal Lubrication, also known as MQL: Minimum Quantity Lubrication. It performs its function by supplying compressed air and minimal amounts of lubricating fluid, including:

– Neat lubricants, typically based on synthetic vegetable esters.

– Water-miscible cooling lubricants.

The LTS.02 is a professional product, offered in a single “full optional” version with Tubo-flex (53) of length 300 mm (art. LTS.02A30) or 390 mm (art. LTS.02A39).

CHARACTERISTICS OF THE MOST COMMON USABLE OILS

Water-miscible oils (also called emulsifiable), whether of mineral, synthetic, or semi-synthetic origin. These lubricating fluids are the most well-known because they are already used in classic continuous jet systems. The fact that all mechanical workshops normally already have this product, in addition to it being the most economical, leads to a prevalent preference for its use.

This product is preferred and recommended by us for use on all OilJet devices, as being water-based, it is less prone to the formation of respirable mist-aerosols.

Neat oils (to be understood as not diluted with water). These lubricating fluids are specially produced for use in MQL (Minimum Quantity Lubrication) systems, a category that includes OilJet products. These are typically of vegetable origin, non-toxic, very fluid, and almost colorless.

As it is a neat product, with equal lubrication and cooling capacity, the quantity dispensed must be significantly lower than the previous one; its higher viscosity (compared to water) automatically serves this purpose. The technical table present on each product sheet demonstrates this comparison.

It should be noted that this category of products is atomized even at low air flows, making it more difficult to reduce aerosol emissions to zero.