Machinery Directive: Tecno Più’s Integrated Solution for Industrial Machinery Compliance

The Challenge of Industrial Safety in Light of the Machinery Directive

In today’s industrial landscape, safety is no longer just a regulatory obligation but a strategic factor that significantly influences business competitiveness. Manufacturing companies face a complex scenario marked by constantly evolving regulations and increasingly sophisticated technological demands.

The Machinery Directive 2006/42/EC and numerous related standards—such as UNI EN ISO 12100:2010 for risk assessment and EN ISO 14120:2015 for fixed and movable guards—impose strict requirements that demand specialized expertise to be properly interpreted and implemented.

For companies operating with outdated or pre-CE machinery, the situation is particularly critical: these systems, while still functionally valid, often do not meet the essential safety requirements defined by current legislation. At the same time, production environments that are integrating new technologies—such as collaborative robots (cobots) or complex automated systems—require solutions that balance innovation with operator protection.

The Consequences of a Fragmented Approach to Safety

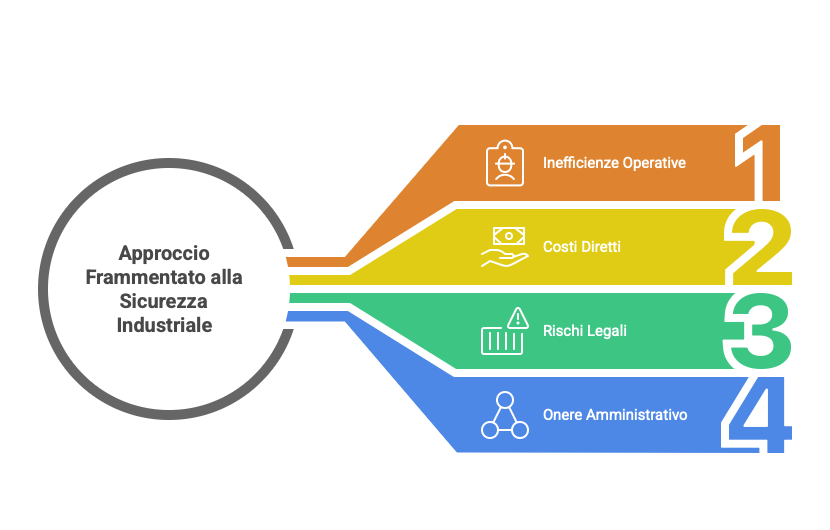

Tackling these challenges with a fragmented approach—relying on multiple providers for each phase of the safety compliance process—introduces significant risks and inefficiencies that can seriously compromise business operations.

The fragmentation of required expertise leads to inefficiencies and potential inconsistencies. When a company has to coordinate regulatory consultants, component suppliers, installers, and certification experts, delays, overlaps, and communication breakdowns are frequent. This scenario of dispersed responsibilities often results in a blame game among providers, leaving the client company exposed and uncertain.

Unplanned or prolonged machine downtimes are a massive direct cost. Every day of inactivity means lost production, delayed deliveries, and potential customer loss. Statistically, a fragmented implementation can increase downtime by up to 60% compared to an integrated approach.

Partial or undetected non-compliance with the Machinery Directive exposes companies to significant legal risks. Penalties for safety regulation violations can be substantial, not to mention the civil and criminal liabilities in the event of an accident.

Managing multiple vendors also adds administrative and organizational burden—often underestimated—that significantly affects both the overall efficiency and the final cost of the project.

In today’s landscape, marked by unprecedented competitive pressure, no company can afford the costs and risks of a fragmented approach to industrial safety..

The 360-Degree Service: Tecno Più's Integrated Approach

Tecno Più has revolutionized the industrial safety sector by developing a fully integrated service model that eliminates the inefficiencies and risks typical of traditional approaches. Our 360-degree service covers the entire lifecycle of the safety compliance process, providing companies with a single qualified point of contact for all phases of the intervention.

Specialized Regulatory and Technical Consulting

The process begins with an in-depth consultation that includes:- Detailed analysis of existing machinery using standardized methodologies

- Risk assessment in accordance with ISO 12100:2010, with a comprehensive mapping of critical issues

- Precise interpretation of the regulations applicable to the specific case

- Development of a customized action plan with prioritization of interventions

Custom Engineering Design

Tecno Più’s technical department develops tailored solutions that combine safety, functionality, and practicality:- Advanced 3D design to ensure perfect integration with existing machinery

- Optimized engineering solutions that preserve full machine operability

- Modular design that facilitates maintenance and future adaptability

Certified Production of Safety Components

Tecno Più manufactures all necessary components in-house, ensuring:- Top-quality materials selected for durability and resistance in industrial environments

- Precision manufacturing using cutting-edge technologies

- Strict quality control at every stage of the production process

- Full traceability of components and materials

COORDINATED PROFESSIONAL INSTALLATION

The installation phase is a critical moment where technical expertise and coordination make all the difference:- Teams of specialized installers with continuous training on regulations and technologies

- Optimized intervention planning to minimize production impact

- Standardized procedures to ensure consistent results

- Complete functional verification and testing according to relevant regulatory parameters

Certification and Complete Documentation

We complete the service with flawless management of all documentation aspects:- Professional drafting of technical documentation in compliance with current regulations

- Detailed declarations of conformity according to the Machinery Directive

- Comprehensive and well-organized technical files, easy to consult

- Clear user manuals compliant with EN ISO 20607:2019

The Tangible Benefits of the Tecno Più Model

Choosing Tecno Più’s 360-degree service means gaining tangible, measurable benefits:

Maximized Operational Efficiency

- Reduction of machine downtime by up to 40–60% thanks to integrated planning

- Elimination of coordination inefficiencies between multiple providers

- Immediate resolution of issues with no shifting of responsibilities

- Faster implementation of safety solutions

Absolute Regulatory Compliance Assurance

- Full compliance with all applicable regulations, with no grey areas

- Elimination of risks tied to partial or inadequate implementations

- Complete protection from penalties and regulatory actions

- Flawless technical documentation for inspections

Economic Optimization of the Investment

- Average reduction of 35% in total compliance costs by eliminating redundancies

- Prevention of costly post-installation corrective actions

- Solutions tailored to actual needs, avoiding overengineering

- Transparent and predictable costs, with no surprises or unexpected extras

Tailored Solutions for Every Industrial Need

Tecno Più’s versatile approach is expressed through customized solutions for various industrial contexts:

Compliance Upgrades for Pre-CE Machinery

For companies operating with machinery built before the Machinery Directive 2006/42/EC, we offer a complete upgrade service that includes:- Technical evaluations based on UNI EN ISO 12100:2010 for residual risk analysis

- Retrofitting interventions to implement modern safety devices

- Full CE recertification with updated technical documentation

- Solutions that extend the useful life of machinery without costly replacements

Protection for Robotic Cells and Automated Systems

For industries implementing collaborative robots (cobots) or advanced automation systems, Tecno Più offers:- Integrated design of robotic cells compliant with ISO 10218-1:2011

- Installation of perimeter protections in accordance with EN ISO 14120:2015

- Smart interlock systems for safe access to operational areas

Solutions for Machine Shops and Machining Centers

Machine shops and metalworking centers benefit from the tailor-made protection systems developed by Tecno Più’s TP-Mod division:- Dynamic enclosures for CNC machining centers that combine protection with accessibility

- Soundproof cabins compliant with the Noise Directive 2003/10/EC

- Modular barriers for complex geometries

Our Commitment: "Safety is not a Target, It is a Way of Life"

Since 1994, Tecno Più has made industrial safety not just a professional activity but a true mission. Our motto, “Safety is not a Target, It is a Way of Life,” perfectly summarizes our philosophy: safety is not merely a goal to achieve, but a way of working that must permeate every aspect of the production process.

We firmly believe that working with quality and safety is not only a regulatory requirement but the first rule of a good worker—and above all, a choice everyone should make. This belief drives every project we undertake, every component we manufacture, and every installation we complete.

Tecno Più’s UNI EN ISO 9001:2015 certification is not just a formal acknowledgment, but tangible proof of our commitment to excellence and quality at every stage of our work. This quality system encompasses the entire production process, from commercial to technical aspects, ensuring our clients receive reliable, innovative, and fully compliant solutions.

Stay Safe

Tecno Più’s 360-degree service is ready to transform your experience in managing industrial safety. Don’t settle for a temporary fix to an immediate problem—invest in an integrated approach that ensures lasting peace of mind, efficiency, and compliance over time.

Get in touch with our team of experts today for a personalized assessment of your machinery fleet or specific operational needs. Together, we’ll analyze your situation and develop a tailored action plan that fits your production environment.

With Tecno Più, compliance is not a final destination but a continuous process of improvement, where every innovation becomes an opportunity to grow in both safety and competitiveness. Because safety is not just an obligation to fulfill—it’s a competitive advantage to seize.

Request a Personalized Assessment

Don’t let the Machinery Directive become a problem. Rely on Tecno Più for integrated, efficient, and well-documented compliance solutions.

Contact us today for a customized technical consultation and discover how to turn safety into a lasting competitive advantage.

Leaders in the Manufacturing of Machine Tool Accessories

Over 30 Years of Experience