Innovative Air-Oil Lubrication Systems for Machine Tools | OilJet

OilJet air-oil cooling system for machine tools: a Complete Range for every Application

The OilJet air-oil cooling systems represent the cutting-edge solution for lubrication and cooling during mechanical machining.

- Chip Removal Machine Tools: Compatible with all known types

- Deformation Machines: Ideal for presses and other similar machinery

- Special Equipment and Machines: Suitable for all specific needs of modern industry

The OilJet cooling systems are based on the technique of Micro-lubrication, using the delivery of small amounts of lubricant carried by a controlled flow of compressed air. This principle is also known by the acronym “MQL” (Minimum Quantity Lubrication).

This occurs through various methods, one of which is the ” Venturi principle,” whereby the fluid contained in the dedicated reservoir is aspirated and subsequently mixed with compressed air, and finally delivered to specific dispensing nozzles specially designed to prevent the formation of mist and unwanted aerosols.

Three Models for Every Machining Requirement

Thanks to these features, the OilJet devices are recommended for use on both new and used machine tools, especially in cases where one opts to replace the original continuous jet system and its associated collection tank.

All of this significantly contributes to environmental protection and operator health.

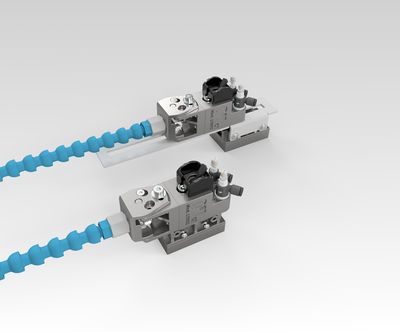

The modularity that characterizes all individual components, as well as the wide range of accessories available in the catalog, allows for immediate customizations and contributes to the rapid expansion of the OilJet range.

Features and Equipment

- Operating pressure: 2 – 6 bar

- Fluid delivery range: 0.1 – 40 cc/min

- Operating temperature: -10°C to +50°C

- Independent micrometric adjustment of air-oil flow

- Integrated pneumatic ON-OFF switch

- 1-liter tank included (optional 2-liter tank available)

- Magnetic base for console support (optional)

- Friction axial adjustment of the consoles on support bracket (upgraded version available as an option)

- Equipped with a detailed Quick Start Guide

Advantages of the OilJet Series

- Significant reduction in lubrication costs

- Improved cleanliness and safety in the work area

- Minimal environmental impact due to reduced lubricant usage

- Improved visibility during machining

- Maximum versatility of use thanks to the wide and diverse range

- Optimized for the use of full lubricating oils and water-oil emulsions

- Reduction of splashes on guards, ensuring optimal visibility

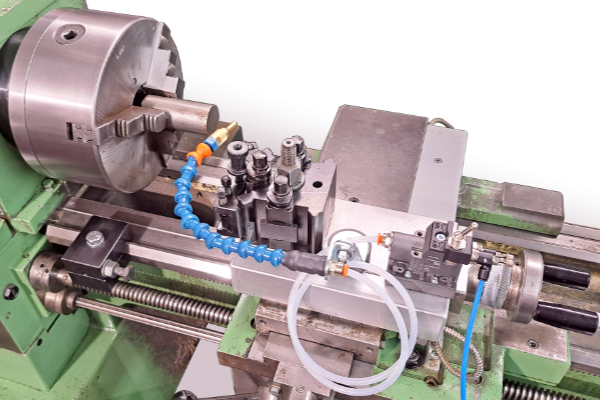

LMG.01 – Air-Oil Cooling System for Parallel Lathes and Generic Machine Tools

Air-oil cooling system available in three versions: Type a – b: Traditional design with a console in simplified configuration (type a) and advanced configuration (type b), both featuring a flexible hose in two lengths (for machine tools with vertical spindles and generic machines). Type C: Equipped with a “satellite” dispensing nozzle hose, available with a flexible hose in three lengths (Specialized for parallel lathes).

LSG.01 – Air-Oil Cooling System for Band Saws and Generic Machines

Available in two versions and multiple variants Type a: version with simplified console and single or double flexible hose, equipped with a cylindrical dispensing nozzle ø4 mm Type b: version with advanced console and single or double flexible dispensing hose equipped with a cylindrical dispensing nozzle ø4 mm

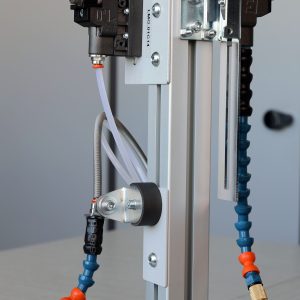

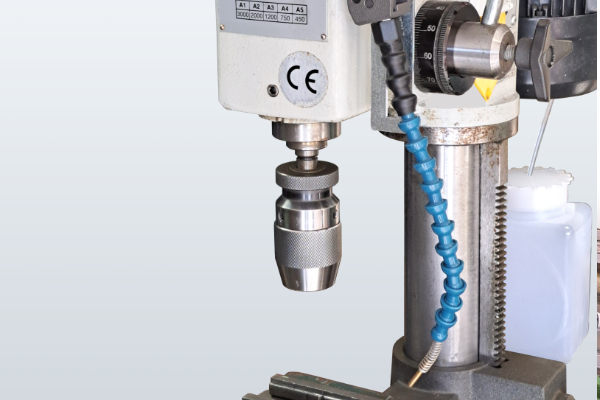

LTS.02 – Air-Oil Cooling System for Drills and Milling Machines

Available in three versions and multiple variants: Type a – b: Traditional design, available with a console in simplified configuration (type a) and advanced configuration (type b), both with a flexible hose in two lengths (for machine tools with vertical spindles and generic machines). Type c: Equipped with a “satellite” dispensing nozzle hose, available with a flexible hose in three lengths (for parallel lathes).

Flexible Applications for Every Industrial Sector

The OilJet series is designed to adapt to a wide range of machine tools, both new and existing:- Conventional and CNC lathes

- Manual and numerical control milling machines

- Column and radial drills

- Band and disc saws

- Work centers and multifunction machines

The OilJet air-oil cooling systems represent the intelligent choice for optimizing your mechanical machining operations.

OilJet air-oil cooling systems : the smartest choice for your mechanical machining operations

Vertical Spindle Machines

For vertical spindle machine tools, such as drills and milling machines, which require frequent tool changes with varying lengths, the LTS.02 model represents the ideal solution. This model stands out for two main features:- A swivel at the base of the flexible hose, allowing quick disengagement from the work area.

- Friction axial adjustment, enabling immediate vertical repositioning.

Generic Machines Requiring a Control Point Separated from the Dispensing Point

For machines that, by nature or for safety reasons, require a control point separate from the dispensing point, the LMG.01C model represents the optimal solution. This model offers:- A satellite dispensing nozzle hose, separated from the console and equipped with its own magnetic base.

- Maximum versatility when paired with the magnetic base kit for console support.

Band Saws and High-Speed Disc Saws for Lightweight Alloys

These machines require a reduced-size dispensing nozzle, powered by a flexible hose. The LSG.01 model perfectly fits these needs, offering:- Single nozzle dispensing hose configuration: ideal for band saws.

- Double nozzle dispensing hose configuration: optimal for high-speed disc saws.

- Are more economical;

- Do not include the pneumatic switch;

- Do not have independent air-oil flow adjustment;

Generic Machines for Occasional Use

For machines used occasionally, where permanent mechanical fastening of the console might be inconvenient, it is recommended to:

- Select the model most suitable for the machine’s specific requirements.

- Pair with the optional magnetic base kit (cod. FL00910) for console support.

This kit (cod. FL00910) offers positioning flexibility:

- Directly on the console body

- On the support bracket with axial adjustment

This solution ensures:

- Ease of installation and removal

- Adaptability to different machine surfaces

- Versatility for temporary uses or on different machines

The magnetic base kit represents an ideal solution to optimize the use of air-oil cooling systems on machines with non-continuous use or in flexible work environments.

“`