In today’s industrial environment, workplace safety has evolved into a critical strategic issue. It’s no longer just about regulatory compliance—it directly impacts a company’s competitiveness and long-term sustainability. Yet many businesses continue to approach this issue in a fragmented way, underestimating the consequences.

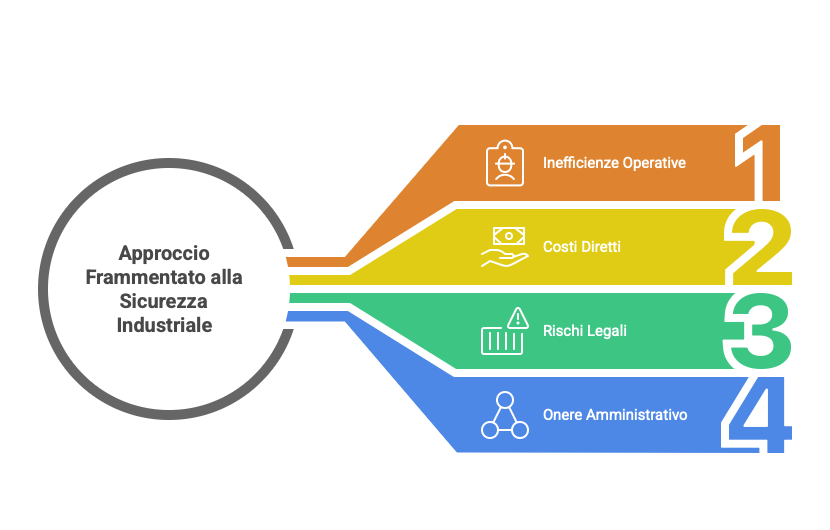

The Fragmentation Trap

When a company relies on separate providers for regulatory consulting, design, component manufacturing, and installation, it exposes itself to risks and inefficiencies that are often overlooked. The data speaks for itself: a fragmented implementation can increase machine downtime by up to 60% compared to an integrated approach.

Imagine this scenario: a compliance consultant identifies non-conformities, a supplier manufactures the required components, and a third-party installer sets them up. It seems linear—but in reality, it often becomes a maze of delays, miscommunication, and blame-shifting, with the client company stuck in the middle.

The True Cost of Non-Compliance

The consequences go far beyond operational inefficiency. Fines for violating safety regulations can be substantial—up to €120,000 in serious cases. This is compounded by the risk of civil and criminal liability in the event of accidents, not to mention the reputational damage that can follow.

A telling example is a packaging manufacturer that faced severe penalties due to non-compliance with conveyor belt protection standards. Only the timely and comprehensive intervention of a specialized partner resolved the situation within 72 hours, avoiding potentially disastrous consequences.

The Integrated Solution: A 360-Degree Approach

The answer to these challenges is a fully integrated approach to industrial safety—one that covers the entire lifecycle of the compliance process. That’s exactly what Tecno Più offers with its 360-degree service.

From initial regulatory consulting to custom engineering design, certified component manufacturing, and professional installation, the Tecno Più model eliminates the inefficiencies and risks associated with traditional approaches. The result? An average 35% reduction in overall compliance costs, up to 60% less machine downtime, and complete regulatory certainty.

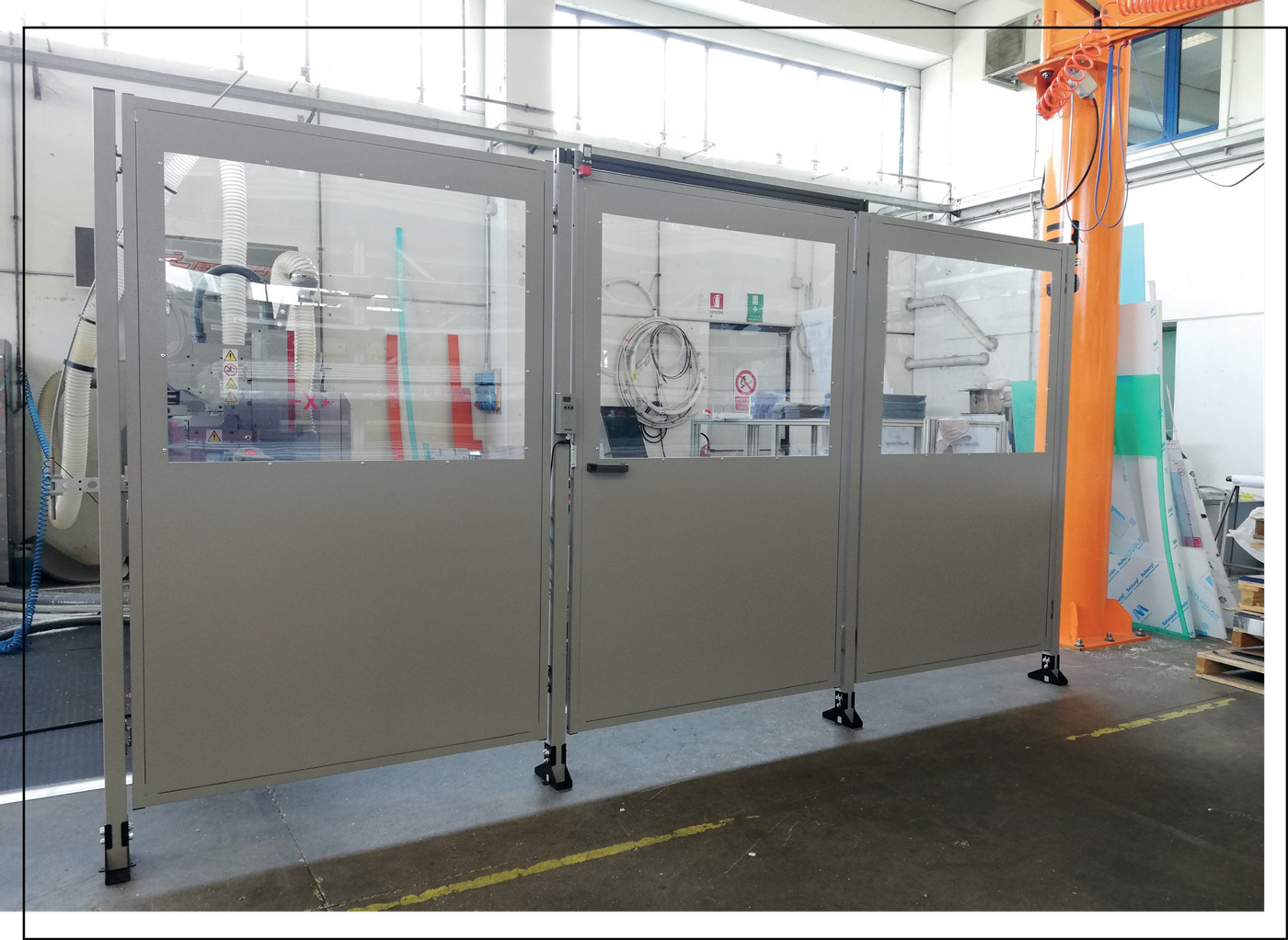

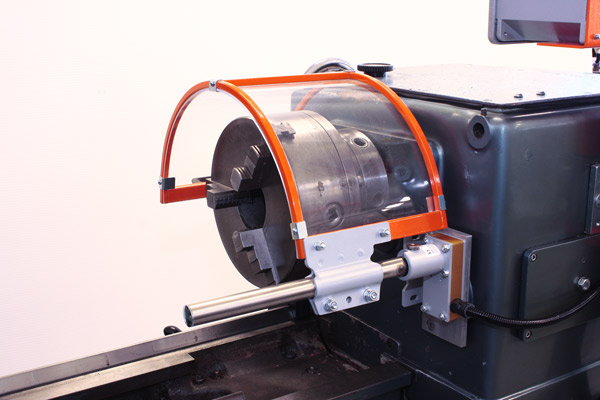

Tailored Solutions for Every Industrial Need

Whether it’s upgrading outdated machinery, protecting robotic cells and automated systems, developing solutions for machine shops, or creating specialized applications for industries such as food and pharmaceuticals, Tecno Più’s integrated approach is perfectly adaptable to any industrial setting.

One example is a dairy facility in Northern Italy, for which Tecno Più developed a conveyor protection system that passed an EFSA audit. Tecno Più solutions ensure both operator safety and full compliance with industry regulations.

A Philosophy, Not Just a Service

“Safety is not a Target, It is a Way of Life”—this motto perfectly captures Tecno Più’s philosophy. Safety is not just a goal to reach, but a way of working that must permeate every aspect of production.

Since 1994, Tecno Più has embraced this belief as its mission, earning UNI EN ISO 9001:2015 certification and developing a quality system that spans the entire production process—from commercial aspects to technical execution.

Turning Safety into a Competitive Advantage

To discover how Tecno Più’s 360-degree service can transform your experience with industrial safety management, we invite you to visit our dedicated page. Don’t settle for a quick fix to an immediate problem—invest in an integrated approach that ensures long-lasting peace of mind, efficiency, and compliance.

Because with Tecno Più, safety isn’t just an obligation—it’s a competitive edge waiting to be seized.

🔎 Want to explore Tecno Più’s integrated solution to the Machinery Directive? Learn more here