Safety Solutions for Industrial and Robotic Machines

Industrial Machine and Robot Safety

In the field of installation and maintenance of industrial and robotic machines, safety is not only a regulatory requirement but also a true competitive advantage. Investing in cutting-edge safety solutions protects operators, increases productivity, and enhances corporate reputation.

Compliance with regulations EN ISO 10218-1:2012 and EN ISO 10218-2:2011 is essential for operating in the industrial robotics sector. These standards define specific requirements for each installation, with potential legal and economic consequences in case of non-compliance.

Tecno Più positions itself as a strategic partner for installers of robotic and industrial machines, offering a wide range of innovative and customized safety solutions. With deep knowledge of safety regulations and extensive experience in the field, Tecno Più designs and manufactures protective systems that strictly comply with current standards, ensuring work environments that are not only safe but also highly productive.

The ability to tailor products to clients’ specific needs and the flexibility to respond to the unique demands of the industrial sector are hallmarks of Tecno Più’s approach.

Critical Issues and Challenges for Installers

- Operational risks in diverse environments: Unique configurations and risks for each client.

- Optimized installation times: The need for rapid implementation without compromising safety.

- Regulatory evolution: Constant updates to machine safety regulations.

- Solution flexibility: Adaptability to machinery of various types and sizes.

- Technological integration: Compatibility of safety systems with existing machinery.

- Collisions with moving parts: Unexpected or uncontrolled movements of robotic arms or mechanical components of industrial machines can cause serious injuries.

- Unauthorized access to hazardous areas: Unsupervised entry into operating zones of running machines can expose personnel to risks of crushing, cutting, or impact.

- Lack of adequate protection: The absence or inadequacy of physical barriers or safety systems can increase the likelihood of accidents during installation and maintenance phases.

Industrial Machine Safety: Tecno Più Solutions

Protective Enclosures

Protective enclosures are engineered safety systems designed to safeguard operators from critical points and inherent hazards of machine tools and industrial machinery.- Dual protection system: Integrated mechanical and electrical safety. These systems provide enhanced safety thanks to dual protection mechanisms (mechanical and electrical) and the use of integrated safety microswitches. The exclusive PB pneumatic lock system (optional) adds an extra level of protection.

- Ergonomic design: Optimization of setup and maintenance operations. Tecno Più’s enclosures are designed for optimized productivity, featuring ergonomic layouts for maximum accessibility and smart opening systems that reduce setup and maintenance times.

- Pre-engineered modular system: Reduced design and installation time. The modular versatility is a key advantage, offering specific solutions for every machine type, with the option for custom tailoring and adaptability to different configurations.

- Ensure comprehensive protection by containing chips and coolants and ensuring regulatory compliance.

- Full certification: Documentation for immediate regulatory compliance. Tecno Più provides comprehensive support, from technical consulting to customized design, installation assistance, operator training, and after-sales service.

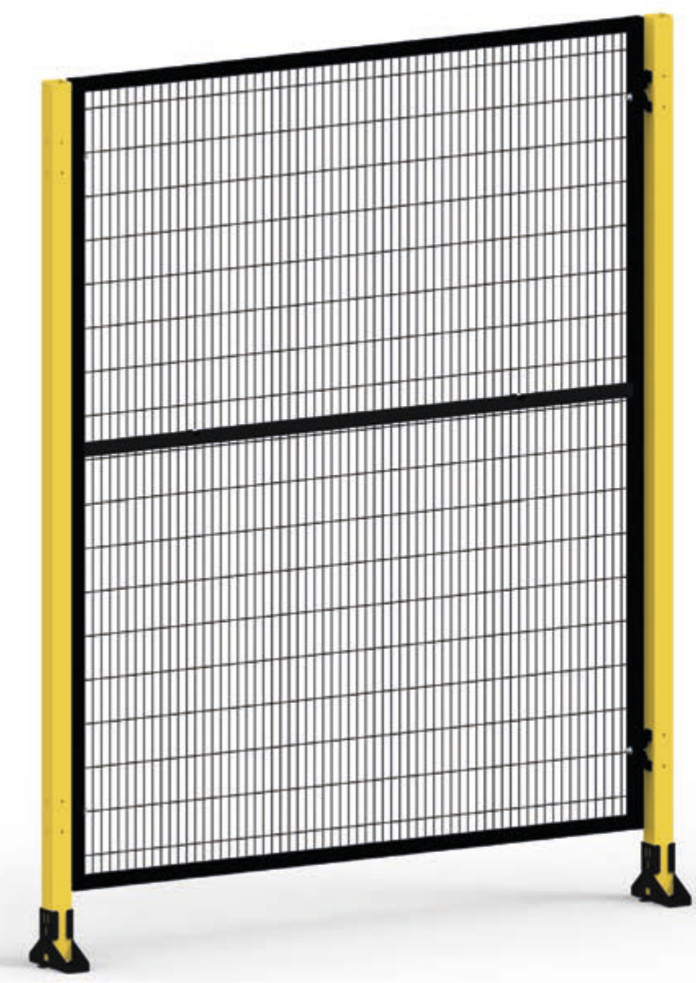

Perimeter Protection Systems

TP-REX perimeter systems are optimal solutions for defining robotic work areas. Perimeter protections are essential for operator safety, preventing unauthorized access or accidental contact with hazardous zones of machine tools and robotic systems.

- These systems define work areas, creating safe perimeters around machines and operational zones to prevent unauthorized access.

- They provide operator protection by preventing accidental contact with moving machinery and other hazardous zones.

- They ensure visibility and controlled access through doors and removable panels.

- Their modularity and adaptability allow system configurations to be tailored to specific plant requirements.

- Tecno Più’s perimeter protections ensure regulatory compliance and contribute to a safe working environment.

- These systems restrict access to hazardous areas or machines to authorized personnel only.

- Tecno Più offers access control systems based on badges, featuring dual-frequency technology for maximum compatibility with existing company badges, ensuring full access traceability and operator safety.

- They help prevent accidents, protect equipment, and maximize productivity.

- Tecno Più’s exclusive access control system offers proprietary technology, superior reliability, and customization.

- Integration with safety systems: Interoperable with perimeter barriers and machine guards, integrable with existing systems.

Tangible Benefits

- Reduced design time: Pre-engineered solutions adaptable to various configurations.

- Lower installation costs: Modular systems that minimize on-site assembly time.

- Increased competitiveness of proposals: Incorporation of cutting-edge safety solutions in the technical offer.

- Complete technical documentation: Certifications and manuals ready for delivery to the end client.

- Dedicated technical support: A team of experts available for consulting on complex projects.

Safety as an Added Value

The quality of safety solutions is a key differentiator in the competitive installation market. Tecno Più’s solutions ensure not only regulatory compliance, but also a true improvement in the working environment and operational efficiency for end clients.Leaders in the Manufacturing of Machine Tool Accessories

Over 30 Years of Experience