Ensuring that machine perimeters are sufficiently robust is crucial for operational safety and regulatory compliance. This requirement is explicitly outlined in the Machinery Directive, which sets the foundation for the safety and protection of workers operating in industrial environments.

Impact Tests for Verifying Robustness

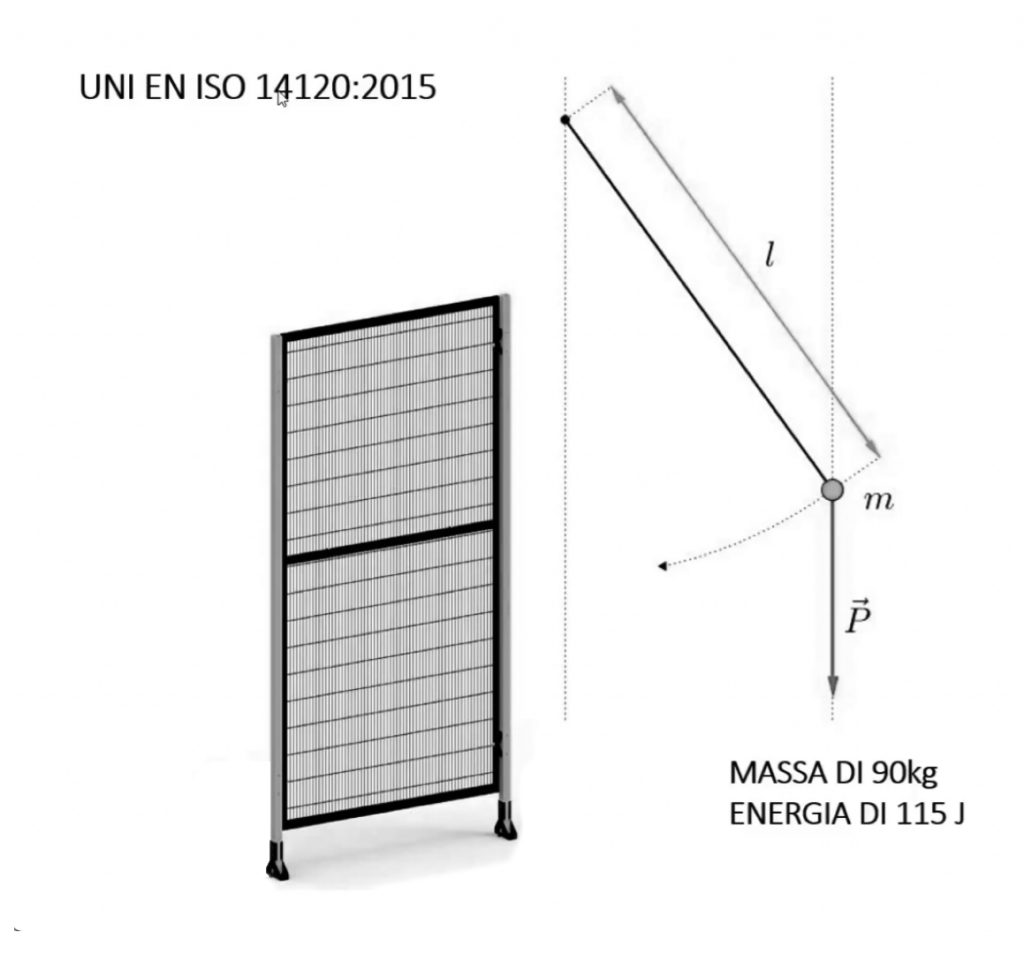

To determine if a guard is sufficiently robust, specific impact tests are conducted. These tests are essential to verify the guard’s ability to withstand mechanical stresses that may occur during use. In particular, two types of impact tests are performed: one with a soft body and one with a rigid body.

Example of Soft Body Impact Test

According to EN ISO 14120:2015, which sets general requirements for the design and construction of fixed and movable guards, the soft body test involves using a mass of at least 90 kg, tied with a rope of adequate length, which must hit the guard with energy of at least 115 joules. In industrial practice, significantly higher energies are often used to ensure broader safety margins.

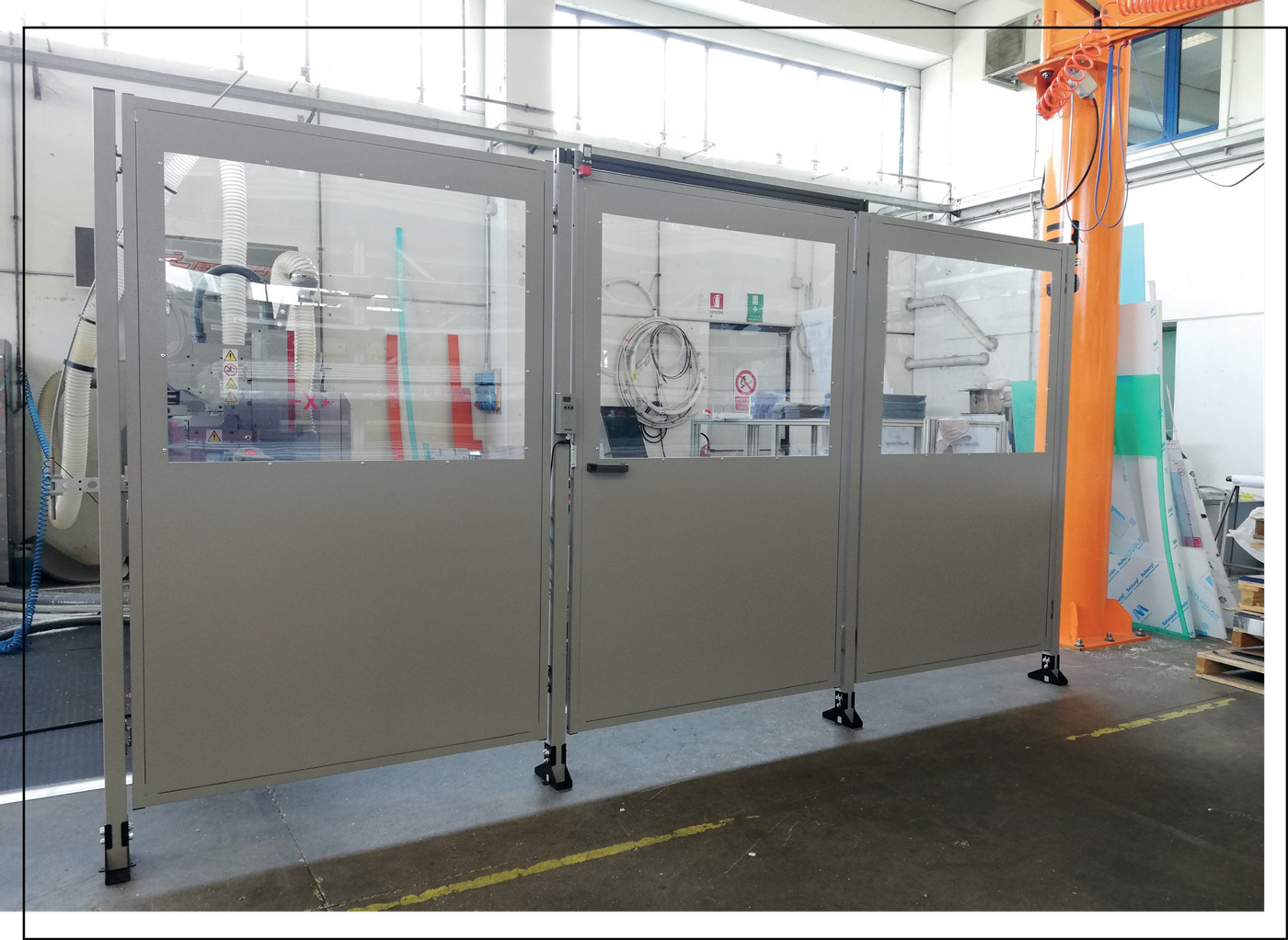

During the test, the deformation of the guard is primarily observed at the feet, near the ground attachments where the mechanical moment is maximum. Despite the deformation, the Tecno Più guard remains intact and continues to fulfill its safety function, effectively protecting the surrounding area.

The Importance of Certified Guards

A critical aspect to consider is the difference between self-made guards and certified guards. If a manufacturer decides to build a guard independently, they will be required to perform all necessary compliance tests to ensure the guard’s safety and robustness. Conversely, by purchasing a certified guard, such as those produced by Tecno Più, the manufacturer receives a certificate that confirms the guard’s compliance with EN ISO 14120:2015.

This standard covers various aspects, including:

-

- Robustness: The ability of the guard to withstand impacts and stresses.

- Color: Standardization of colors to ensure visibility and recognizability.

- Mesh Arrangement: The size and distribution of the mesh to prevent unauthorized access and protect operators.

Impact Testing: How to Verify Robustness

To verify the robustness of guards, two types of impact tests are conducted: one with a soft body and one with a rigid body.

➡️ Soft Body Test: The ISO 14120 standard specifies that for this test, a mass of at least 90 kg tied to a rope is used. The mass must hit the guard with a minimum energy of 115 joules, but in practice, higher energies are used.

Conclusion

In summary, the robustness of machine perimeters is essential for operational safety. Compliance with the Machinery Directive and EN ISO 14120:2015 ensures not only adherence to regulations but also that guards effectively perform their protective function. Relying on certified guards, such as those from Tecno Più, represents a choice for safety and quality, reducing operational risks and protecting both workers and industrial equipment.

For more information on machine perimeter guards, visit the TP-REX website: TP-REX : https://www.tp-rex.com/en/